Research

The main research interest of Dr. Sebaey is the damage and failure of laminated composite materials and structures. His Master thesis title was “Analysis of Bolted Joints of Composite Structures”. The PhD thesis entitle “Characterization and Optimization of Dispersed Composite Laminates for Damage Resistant Aeronautical Structures”. His postdoctoral research was conducted under the umbrella of the NPRP project “Novel Multifunctional Composite Sandwich Panels For Oil and Gas applications”, funded from the QNRF. As it can be noted from the titles, the aim is to design new composites that can be used for Oil and Gas to avoid the corrosion problems in the normal planet infrastructures and piping materials (carbon steel structures).

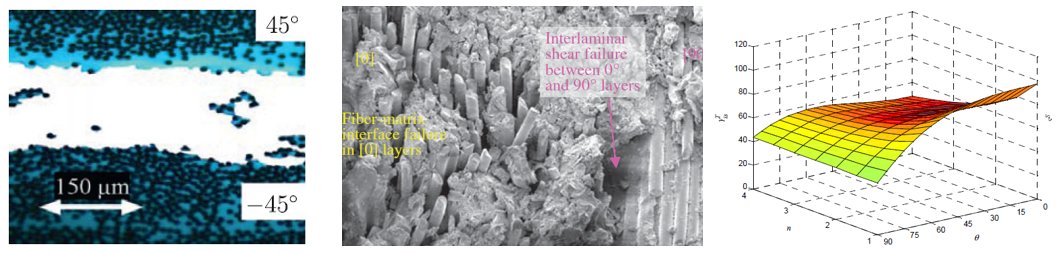

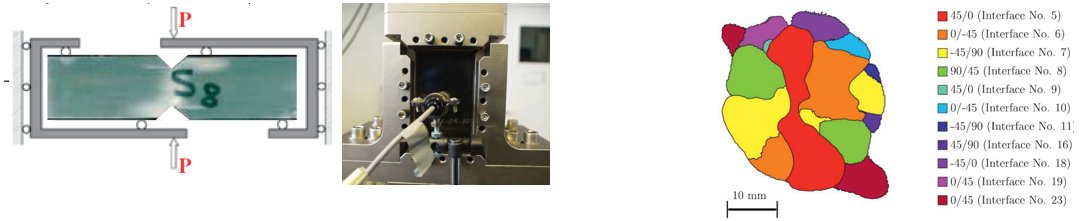

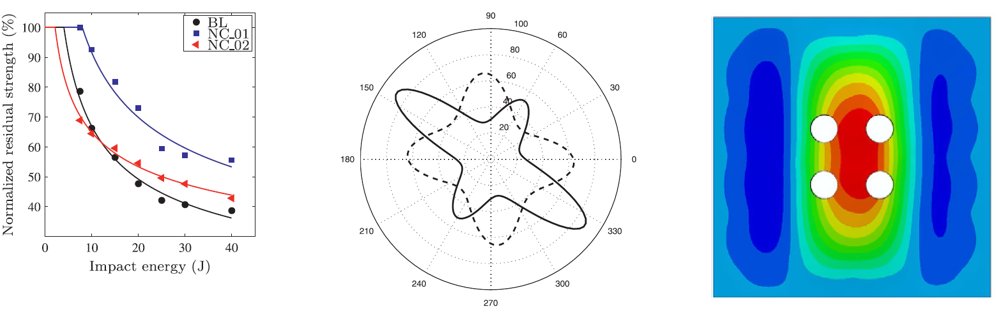

Problems of interest for Dr. Tamer include bolted and adhesive joints in laminated composites, fracture toughness of multi-directional and unidirectional laminates, lamina in-site strength, failure criteria for laminates, mechanics of ultra-thin plies, lattice core sandwich structures, impact and compression after impact of composite plates, energy absorption device made of composite structures, fracture under internal pressure of composite pipes and dispersed laminates. Research tools used by Tamer include FE simulation, Optimizations using ant colony algorithm ACO, mechanical testing, optical and SEM microscopy, computed tomography, digital image correlation and drop-weight impactor.

Research Projects:

Research Projects:

VLANCO, Project ID: MAT2009-07918 2009-2012 Funded by the Ministerio de Ciencia e Innovacion, Spain.

Summary-Composite materials are extensively used in aeronautical composite parts. Nowadays, huge effort is oriented to the characteristics of non-conventional laminates as a promising technology to replace the conventional ones. Non-conventional laminate can be divided into variable stiness panels (in which the ber path is curved) and dispersed laminates (where straight bers are used but at angles dispersed throughout the whole 0-90 range). The project aimed to use the huge manufacturing potential of the automated ber placement technology to manufacture a pre-designed non-conventional panels and test them in our lab. This project is now 0. The project ended by 12 Journal papers and more than 15 conference communications. I was the corresponding author of 9 journal papers and more than 10 conference communications in this project.