Research

Current Research Activities and Interests:

My research activities and interests primarily fall into the following broad research themes:

- Integrated Multi-scale Modelling-Simulation (MMS) and Machine Learning (ML) based Design and Development of Novel Technologies/systems/processes: Application on energy storage systems: Machine Learning- assisted Multi-scale Modeling and Simulation of Na-ion rechargeable batteries and organic flow battery systems, especially focus on Machine Learning (ML)+ Density functional theory (DFT) + Computational fluid dynamics (CFD) simulations. MMS+ML based material selection/design and experimental design. Reversible screening/validation (experimental screening+ computational screening. Application in developing membrane technologies: The application of ML in developing membrane technologies for gas separation and water treatment. Machine Learning- assisted Multi-scale Modeling and Simulation of gas separation and water treatment membrane systems and processes.

- Multi-scale Modeling and Simulation and Multi-scale Modeling and Simulation- based experimental design: The areas of reaction engineering and reactor design (Conventional reactors, Membrane reactors-MR Adsorbent reactors-AR and Hybrid reactors): multi-scale modeling and simulation of transport in complex porous media; the study of transport and reaction phenomena in membranes, adsorbents, and catalysts. Experimental studies on MR, AR and hybrid reactors.

- Sustainable development and Sustainability Assessment.

- Environment and Pollution Prevention: CO2 capture, utilization, and storage.

- Energy: Multi-scale modeling and simulation of energy systems. Hybrid reaction/separation systems for H2 production and electricity, analysis of biomass-based and hybrid energy/hydrogen production potentials and systems.

- Economic profitability and sustainability assessment of chemical processes, through Life Cycle Assessment (LCA) and Techno Economic Analysis (TEA).

- Metal (Boron etc.) Combustion: Multi-scale Modeling and experimental studies on metal combustion processes.

- Machine learning (Artificial Neural Networks etc.) applications on chemical processes and energy systems.

- Applied mathematics.

CONTRACTS, GRANTS and SPONSORED RESEARCH

- Karagoz, S. (Research assistant), “An investigation of the removal of CO2 and SO2 in thermal power plant flue gases by waste ulexite ore”, TUBITAK (The Scientific and Technological Research Council of Turkey).

- Karagoz, S. (Research assistant), “A High Efficiency, Ultra-Compact Process for Pre-Combustion CO2 Capture”, USA DOE, 450,000.00 USD.

- Karagoz, S. (Lead Principal Investigator), “Design, Simulation, and Integration of Intensified Dimethyl Ether (DME) Production,” Qatar University, 7,000.00QR.

- Karagoz, S. (Lead Principal Investigator), “Multi-scale Modelling and Intensification of Dimethyl Ether (DME) Production,” Qatar University, 7,000.00QR.

- Karagoz, S. (Lead Principal Investigator), “Process Intensification by Reactive-Separation Systems: Hydrogen Production and CO2,” Qatar University, 7,000.00QR.

- Karagoz, S. (Lead Principal Investigator), “Technology Assessments for Process Intensification in Qatar” Qatar University, 7,000.00QR.

- Karagoz, S. (Principal Investigator), “The Application of Machine Learning in Developing Membrane Technologies,” Internationally Collaborative Grant.

- Karagoz, S. (Lead Principal Investigator), ” Multi-Scale Modeling and Simulation of Hydrogen Production Processes” Qatar University, 7,000.00QR.

- Karagoz, S. (Lead Principal Investigator), ” Intensified and Modular Hydrogen Production” Qatar University, 7,000.00QR

- Karagoz, S. (Lead Principal Investigator), ” Methodological Sustainability Assessment for the Design of Alternative Ethylbenzene Production Processes” Qatar University, 10,000.00QR.

- Karagoz, S. (Lead Principal Investigator), ” Design and Optimization of an Ethylbenzene Production Plant” Qatar University, 10,000.00QR.

- Kahraman, R. (Lead Principal Investigator), Alqaradawi, S. Y. A. (Principal Investigator), Shakoor, A. (Principal Investigator), Karagoz, S. (Principal Investigator), Youssef, K. M. (Principal Investigator), “Novel High Entropy-cation Disordered Rock Salt (HE-DRX) Positive Electrode Materials for Na-ion Rechargeable Batteries: An Experimental and Theoretical Approach, QUHIG-2024\2025-427,” Qatar University, 600,000.00QR. (2024 – 2026).

CURRENTLY Under REVIEW GRANTS:

- Karagoz, S. (Lead Principal Investigator), “Multi-scale modeling-simulation based design of organic redox flow batteries,” Qatar University, 600,000.00QR.

- Karagoz, S. (Principal Investigator), “Anode-Free Lithium Metal Batteries: Impact of high voltage Spinel LiNi0.5Mn1.5O4 cathode material on the electrochemical performance,” Qatar University, 30,000.00QR.

- Karagoz, S. (Principal Investigator), “Next Generation Battery Packs for Protracted Urban Electric Mobility,” Qatar University, 400,000.00QR.

- Karagoz, S. (Principal Investigator), “Tailored Electrode Materials for Hybrid Supercapacitors: A new Trend in Electrochemical Energy Storage,” Qatar University, 600,000.00QR.

- Karagoz, S. (Lead Principal Investigator), ” Integrated machine learning and multi-scale modeling and simulation based novel process development: CO2 capture and release it as a high-value fuel or chemical” Qatar University, Internationally Collaborative Grant, 160,000.00 USD.

- Karagoz, S. (Lead Principal Investigator), “The Application of Machine Learning in Developing Membrane Technologies,” Qatar University, 300,000.00QR.

- Karagoz, S. (Lead Principal Investigator), “The Application of Machine Learning in Developing Membrane Technologies,” Qatar University, 160,000.00 USD.

- Karagoz, S. (Principal Investigator), “Dry reforming of methane – Theoretical and Experimental approaches,” Local(Excluding Qatar University), 600,000.00US.

- Karagoz, S. (Principal Investigator), “Solar Energy Driven CO2 Recycling and Waste Water Treatment Using Metal Catalysts,” Regional, 599,775.00US.

Research Philosophy:

Research Methodology

Hierarchical theoretical and experimental approaches to novel technology/system/process development and problem solutions:

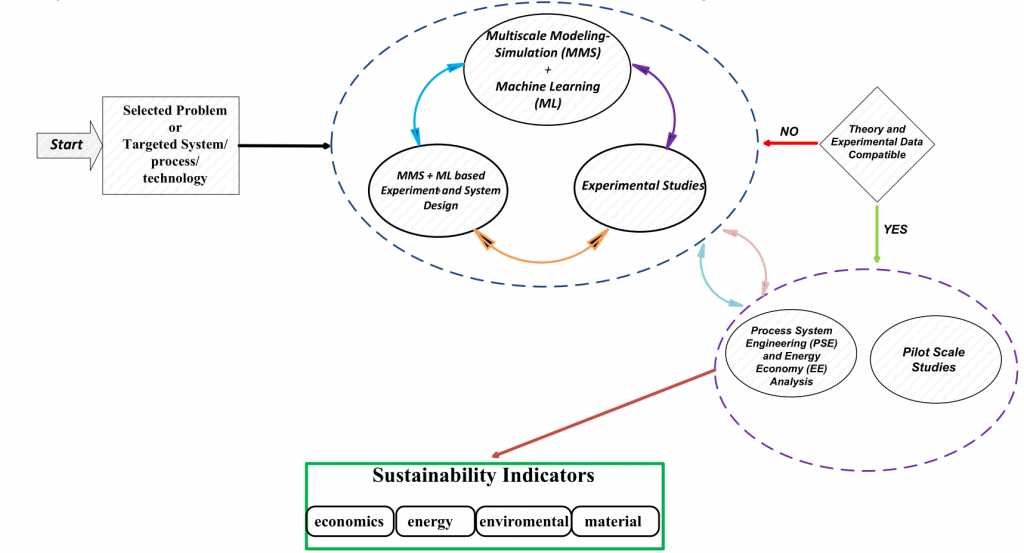

Traditionally, the development of new technologies/systems/processes is complemented by testing. Experimental tools for testing and examining the results are expensive, and their use is time-consuming. In recent years, thanks to the rapid growth in computational speed, it has been seen that the use of computer-aided methods in the design phase contributes greatly to the reduction of cost and time for the entire technology development process. Moreover, the simultaneous use of computational and experimental tools allows to tackle problems that cannot be solved using theoretical or experimental methods alone. Thus, my research methodology focuses on developing and applying hierarchical theoretical and experimental approaches to novel technology/system/process development and problem solutions. Integrated Multi-scale Modelling-Simulation (MMS) and Machine Learning (ML) approach allows many systems/processes to be accurately simulated and many process parameters to be calculated without the need for experiments before performing expensive and time-consuming experiments and tests. Research methodology consists of the simultaneous application of ML-assisted MMS, ML+MMS -based design, ML+MMS -based experimental studies, Process System Engineering (PSE) and Energy Economics (EE) calculations, Sustainability Assessments and reversible screening/validation (experimental screening and computational screening or experimental validation and computational validation).

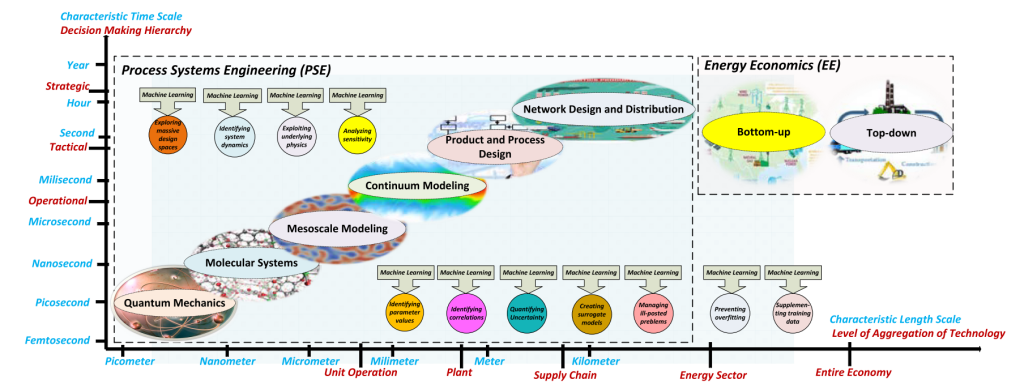

Integrated Multi-scale Modelling-Simulation (MMS) and Machine Learning (ML) Approach: ML-assisted quantum, atomistic/molecular, mesoscale, and large-scale modeling and simulation, as well as process systems engineering + energy economics (design, synthesis, analysis, and optimization), are used for technology/system/process development and problems solutions. Density Functional Theory (DFT), Molecular Dynamics (MD), global optimizations, Computational Fluid Dynamic (CFD) and large-scale calculations are performed. Especially, to accomplish all these goals, the various software combinations such as Gaussian/MATLAB/COMSOL/AspenPlus(HYSYS)/ChemCad etc are utilized. And ML algorithms are adopted to MMS to eliminate weaknesses of the MMS and to create robust predictors/design proposers.

Multi-scale Simulation Based Experimental Design, and Experimental Studies: The objective is the simulation based experimental design and experimentally characterize the entire process/system by lab-scale testing of the individual technology components. The goal is to: (i) design the experiments based on the theoretical findings; (ii) measure the properties under realistic process conditions; and (iii) provide the experimental database required to validate the fidelity of the system models.

Process System Engineering (PSE), Economics and Sustainability: The goal is to apply a novel application of systems engineering framework towards the optimal design of such systems with improved efficiency and environmental performance. The optimization techniques and strategies are performed for various technology alternatives by considering simultaneous economic and environmental criteria. Techno-Economic Analysis (TEA), Life Cycle Analysis (LCA), Sustainability Assessment and Sensitivity Analysis (SA) of systems are performed.

Methodological Sustainability Assessment to Novel Technology/System/Process Development (MSAtoNTSPD): The framework for Methodological Sustainability Assessment to Novel Technology/System/Process Development (MSAtoNTSPD) is introduced as a methodological approach with appropriate sustainability indicators that ensures the capability of gathering and abstracting the complex technology/system/process operations, and that offers clear analysis and communication. In our approach, (MSAtoNTSPD) is consists of 7-phases.

Sustainability is the concept of meeting today’s needs without compromising the ability of future generations to meet their own needs. Sustainability criteria can be divided into three dimensions: Economic, Environmental and Social. Modeling sustainability criteria in decision making in PSE is a relatively new trend. Techno-economic modeling covers the determination of the economic performance of the designed process. Environmental criteria focus on modeling the impact of systems on the environmental ecosystem and require the calculation of two factors: Pollutant and greenhouse gas emissions and environmental impacts due to the primary sources used by the system. Social criteria include the cultural and personal connection with technology and the way it affects society (such as convenience, politics, personal values and beliefs, human behavior and emotional factors).

Developing novel technologies/systems/processes or enhancing the existed ones based on sustainability standards is crucial for eliminating the economic and energy penalties. However, the development of sustainable industrial technologies/systems/processes is the sectors’ challenging global goal. The integration of sustainability into design contributes to the achievement of this target by eliminating or minimizing negative effects. However, measuring sustainability performance and decision-making are crucial and challenging processes for determining sustainability levels. Thus, the development of a methodological approach, ensures the capability of gathering and abstracting the complex process operations, and provides straightforward analysis and communication , with proper sustainability indicators is required. Methodological Sustainability Assessment is a powerful tool for any scale, assisting the designer in obtaining a comprehensive performance evaluation. Economics, energy, environmental, and material efficiency are the main aspects of sustainability to measure sustainable performance levels. To evaluate process sustainability by considering the aforementioned aspects, we propose MSAtoNTSPD as a methodological approach. This approach has the capability and flexibility to be implemented at different scales, such as equipment, technology/system/process units, or the entire technology/system/process, by enabling a direct comparison among the several alternatives that target the same product by using different designs. More importantly, this methodology can be easily used by a designer or researcher to evaluate the sustainability performance after making process modifications.

Field study of the proposed/developed technologies/systems/processes: Operation of the pilot-scale technologies/systems/processes under the target operating conditions, and long-term operational stability test is performed. This section includes;

Operation of the pilot-scale technologies/systems/processes: The technologies/systems/processes are tested under the target operating conditions using the pilot-test unit(s). A complete dataset is generated for each set of operating variables for performing materials balance to assess the quality of the data and verify the applicability of the mathematical models. Long-Term Operational Stability Test: Once the technologies/systems/processes achieve the targeted operation conditions, the test technologies/systems/processes are operated continuously, in order to demonstrate performance stability.